The Evolution of Elliptical Machines: Embracing New Composite Materials for Enhanced Durability and Performance

2024-11-05 17:00Elliptical machines have long been a staple in gyms and households around the world, offering a low-impact yet highly effective workout. As technology advances, so do the materials and methods used in the manufacturing of these machines. In recent years, the fitness equipment industry has seen a significant shift towards the use of advanced composite materials. These materials are revolutionizing the way ellipticals are designed, manufactured, and utilized, leading to machines that are more durable, efficient, and user-friendly.

The Rise of Composite Materials

Composite materials are engineered by combining two or more constituent materials with different physical or chemical properties to produce a material with characteristics different from the individual components. These materials are designed to achieve specific performance objectives, such as high strength, lightweight, and resistance to environmental factors.

In the context of elliptical machines, the introduction of composite materials has brought several benefits:

1. Enhanced Durability: One of the primary advantages of composite materials is their increased durability. Traditional materials like metals and plastics, while effective, often fall short in terms of wear and tear resistance over time. Composites, on the other hand, are designed to withstand high stress and repeated use without compromising their structural integrity. This makes them ideal for fitness equipment that undergoes extensive use.

2. Weight Reduction: Another significant advantage of composite materials is their lightweight nature. Ellipticals made from composites are easier to move and handle, making them more accessible to a wider range of users. This also translates to lower shipping costs and easier installation for both home and commercial use.

3. Improved Performance: The unique properties of composite materials allow for better design flexibility. Engineers can create components with specific properties tailored to the needs of the user. For example, parts of the machine that experience higher loads can be made stronger and more resilient, while other areas can be optimized for weight reduction. This results in a more efficient and effective workout experience.

4. Environmental Impact: Many composite materials are designed with sustainability in mind. They can be manufactured using recycled materials, and their longer lifespan means less frequent replacements and reduced waste. This aligns with the growing consumer demand for environmentally friendly products.

Recent Innovations in Composite Materials

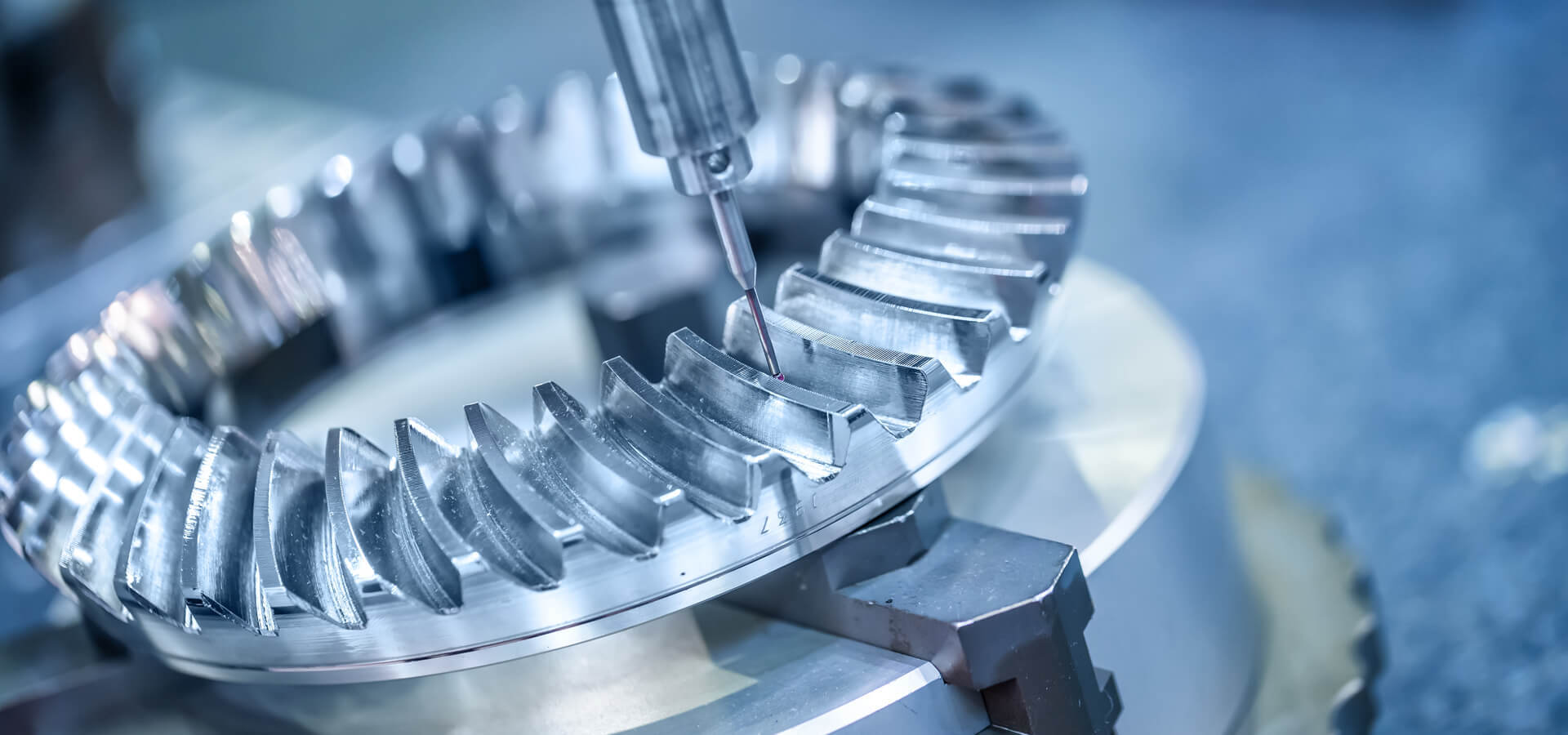

Several innovations in composite materials are currently shaping the future of elliptical machines. These include advancements in high-performance composites, industrial applications, and ongoing research in new material development.

1. High-Performance Composites: Companies are now utilizing high-performance composites such as carbon fiber-reinforced polymers (CFRP). These materials offer exceptional strength-to-weight ratios, making them perfect for use in fitness equipment. CFRP components are not only lightweight but also extremely strong, providing a durable and stable platform for users.

2. Industrial Applications: The use of composite materials is not limited to fitness equipment. Industries such as aerospace, automotive, and construction have long benefited from the advantages of composites. The technology transfer from these sectors to the fitness industry has been seamless, allowing for the incorporation of proven materials and manufacturing techniques into the design of elliptical machines.

3. Research and Development: Ongoing research into new composite materials continues to yield promising results. Institutions and companies are exploring novel combinations of fibers and resins to create materials with even better performance characteristics. For example, hybrid composites that combine carbon fiber with other fibers like Kevlar are being developed to enhance impact resistance and flexibility.

Case Studies and Real-World Applications

Several manufacturers have already begun incorporating composite materials into their elliptical machines, showcasing the tangible benefits of these advancements.

1. Brand A: This leading fitness equipment manufacturer has introduced a line of ellipticals featuring carbon fiber-reinforced frames. These machines are not only lighter and easier to maneuver but also demonstrate superior durability, even under heavy use in commercial gym environments.

2. Brand B: Another innovator in the industry, Brand B, has developed ellipticals with composite pedal arms that significantly reduce the overall weight of the machine without compromising strength. Users have reported smoother and more stable workouts, attributing this to the improved structural integrity provided by the composite materials.

3. Research Institute: A renowned research institute has published studies demonstrating the benefits of hybrid composites in fitness equipment. Their findings suggest that these materials can enhance the lifespan of ellipticals by up to 30%, offering a cost-effective solution for both manufacturers and consumers.

Future Prospects

The integration of composite materials in elliptical machines is just the beginning. As research continues and manufacturing processes become more refined, the potential for further improvements is immense. Future innovations may include smart composites with embedded sensors to monitor equipment usage and performance in real time, providing valuable data for both users and manufacturers.

Moreover, as consumer awareness of the environmental impact of their purchases grows, the demand for sustainable and eco-friendly fitness equipment is likely to increase. Composite materials, with their durability and potential for recyclability, are well-positioned to meet this demand.

In conclusion, the use of advanced composite materials in elliptical machines marks a significant step forward for the fitness equipment industry. These materials offer a unique combination of durability, lightweight, and performance, addressing many of the challenges faced by traditional materials. As manufacturers continue to innovate and incorporate these materials into their designs, users can look forward to more efficient, reliable, and eco-friendly elliptical machines in the years to come.

Related: Weldconn Commercial Fitness Equipment;

Weldconn Light Commercial Fitness Equipment;

Weldconn Home Use Fitness Equipment